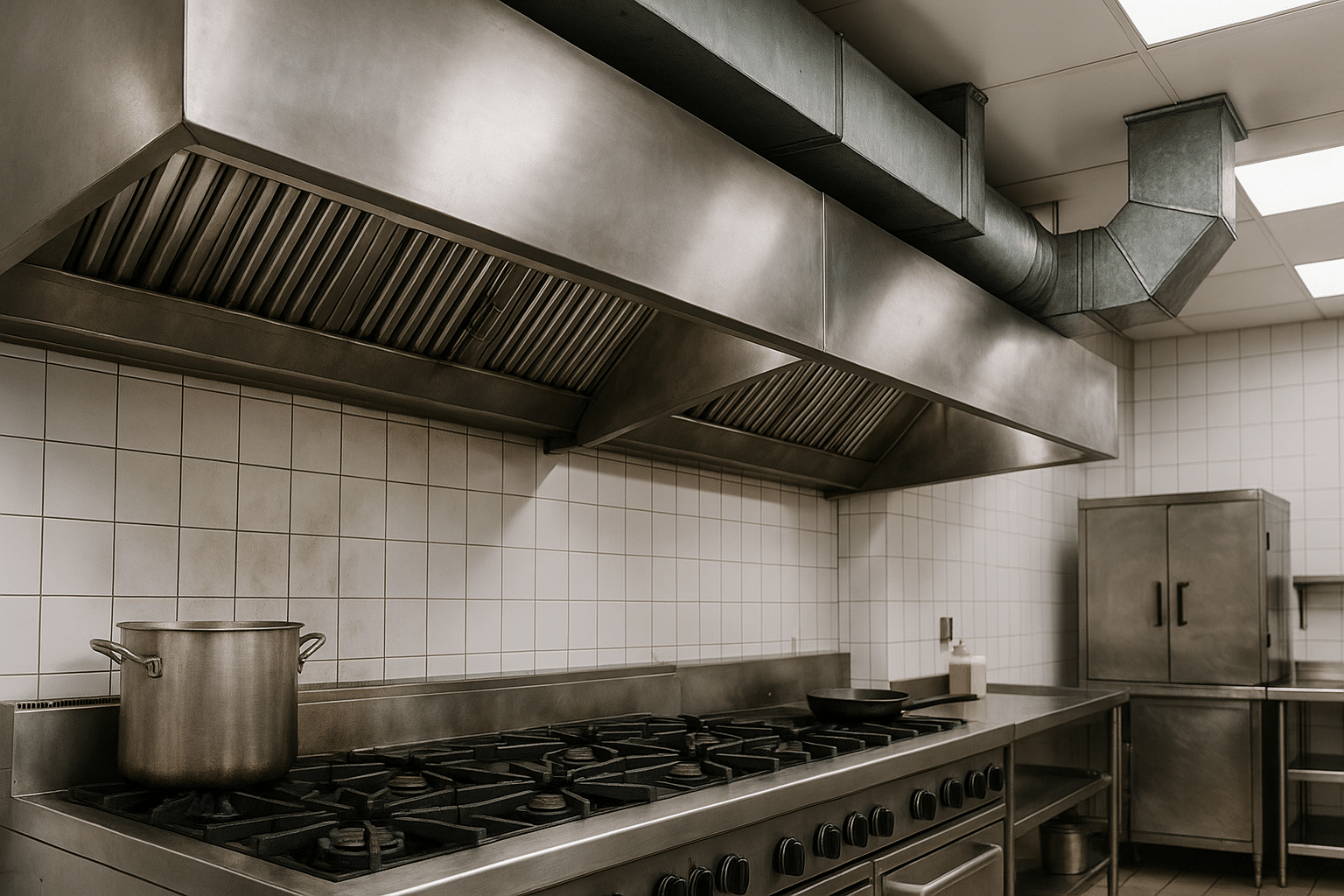

If you run a restaurant, cafe, or institutional kitchen in Salt Lake City, you probably think about food quality, customer service, and payroll every day. But here’s something most business owners underplay: the condition of your kitchen’s ventilation. Regular kitchen vent hood inspections aren’t glamorous. They don’t show up on menus. Yet they quietly protect your staff, your customers, and your bottom line — often in ways you don’t notice until it’s too late.

Why inspections matter — and why they’re not the same as a quick clean

Let me explain. You can have clean-looking hoods and still have serious problems. Grease build-up on visible surfaces is one thing; grease deep inside ductwork, fans, and filters is another. Those hidden layers trap smoke, particulates, and heat. Over time they cook into a sticky, flammable mess. That’s not just messy — that’s risky.

So when we talk about hood cleaning we’re not just wiping stainless steel. Inspections look deeper. They assess mechanical performance, structural integrity, and code compliance. You know what? That difference saves kitchens from fires, citations, and costly downtime.

Health risks you might overlook (and why your staff will thank you)

Cooking releases oil droplets, carbon monoxide, nitrogen dioxide, and fine particulates. Those things hang in the air if extraction isn’t working right. Over weeks and months, staff who breathe that air can develop headaches, sore throats, and long-term respiratory issues. Customers notice odors and poor air quality too — a subtle trust-breaker.

Here’s the thing: you might think “We have vents, so we’re fine.” That’s often not true. Fans lose suction, filters get clogged, and motors wear. Inspections catch these problems early. They preserve indoor air quality and reduce sick days. They also lower insurance risk — which indirectly affects your cash flow.

Fire risk and compliance — yes, they’re connected

Restaurant fires often start with grease. A little flare-up can climb to a major event if grease is caked inside ducts. Fire marshals look for records of inspection and cleaning for a reason: they want to see preventative maintenance that’s documented and real.

It may feel annoying to keep records, but honest record-keeping saves sites from fines and shutdowns. And there’s a mild contradiction here: inspections can be inconvenient, yet they’re often faster and cheaper than dealing with a fire. What would you rather pay for — an inspection or a rebuild?

Operational perks — it’s more than safety

Regular inspections boost performance. Fans run more efficiently, kitchen temperatures stabilize, and equipment lasts longer. That’s the kind of unseen savings that adds up over months and years.

Think about energy bills. A clogged motor pulls more amps. Replace worn belts and bearings and you’ll shave costs. It’s boring math, but it’s real money. Honestly — sometimes an inspection pays for itself in a single season.

What inspectors look for — a short checklist

- Exhaust airflow — Is the system pulling air properly? Measured with an anemometer or obvious by smoke tests.

- Grease accumulation — Not just on the hood but inside ducts and fan housings.

- Filters and baffles — Are they intact and correctly seated?

- Fire suppression interface — Do automatic systems and shutoffs function?

- Electrical and motor health — Are belts, bearings, and wiring safe?

- Structural condition — Any corrosion, gaps, or animal access points?

Inspectors use tools like borescopes, thermal cameras, and airflow meters — and sometimes a basic flashlight and good experience. Brands like Fluke for thermal work and Extech for meters are common in the trade. That gear helps find problems you can’t see with the naked eye.

How often should you schedule inspections in Salt Lake City?

There’s no one-size-fits-all answer. It depends on the menu and volume. High-volume fryers and wok stations mean more frequent checks. A small bakery might need less. Local weather also matters: wildfire smoke in late summer can load HVAC systems with particulates, and winter temperature inversions in the valley can make ventilation less effective.

General guidance:

| Kitchen Type | Inspect Frequency | Risk Level |

|---|---|---|

| High-volume (fast food, 24/7) | Monthly to quarterly | High |

| Full-service restaurants | Quarterly | Moderate |

| Light cooking (cafeterias, coffee shops) | Semi-annual | Lower |

These are guidelines. Your local fire code and insurance may require different schedules. It’s worth asking your inspector for a plan that matches your operations.

Who should do the inspection — and what to expect

Hire a certified technician familiar with NFPA 96 — that’s the standard for ventilation control and fire protection of Commercial cooking operations. Certification matters because inspectors document findings, provide service histories, and can recommend repairs that meet code.

During an inspection expect these steps: a visual walk-through, airflow testing, Filter and fan checks, and photographed evidence for your file. If don’t like paperwork, don’t worry — the best companies (we won’t name names — but companies like ours) make record-keeping painless.

Ready to keep your kitchen healthy, safe, and compliant?

If you own a business in Salt Lake City, regular kitchen vent hood inspections are a simple way to protect people, protect property, and save money over time. It might not be thrilling. But it’s practical, necessary, and — frankly — one less worry on your plate.

Call Utah Hood Cleaning at 801-853-8155 to schedule an inspection today. Or Request a Free Quote and we’ll walk you through a plan tailored to your operation and local requirements.