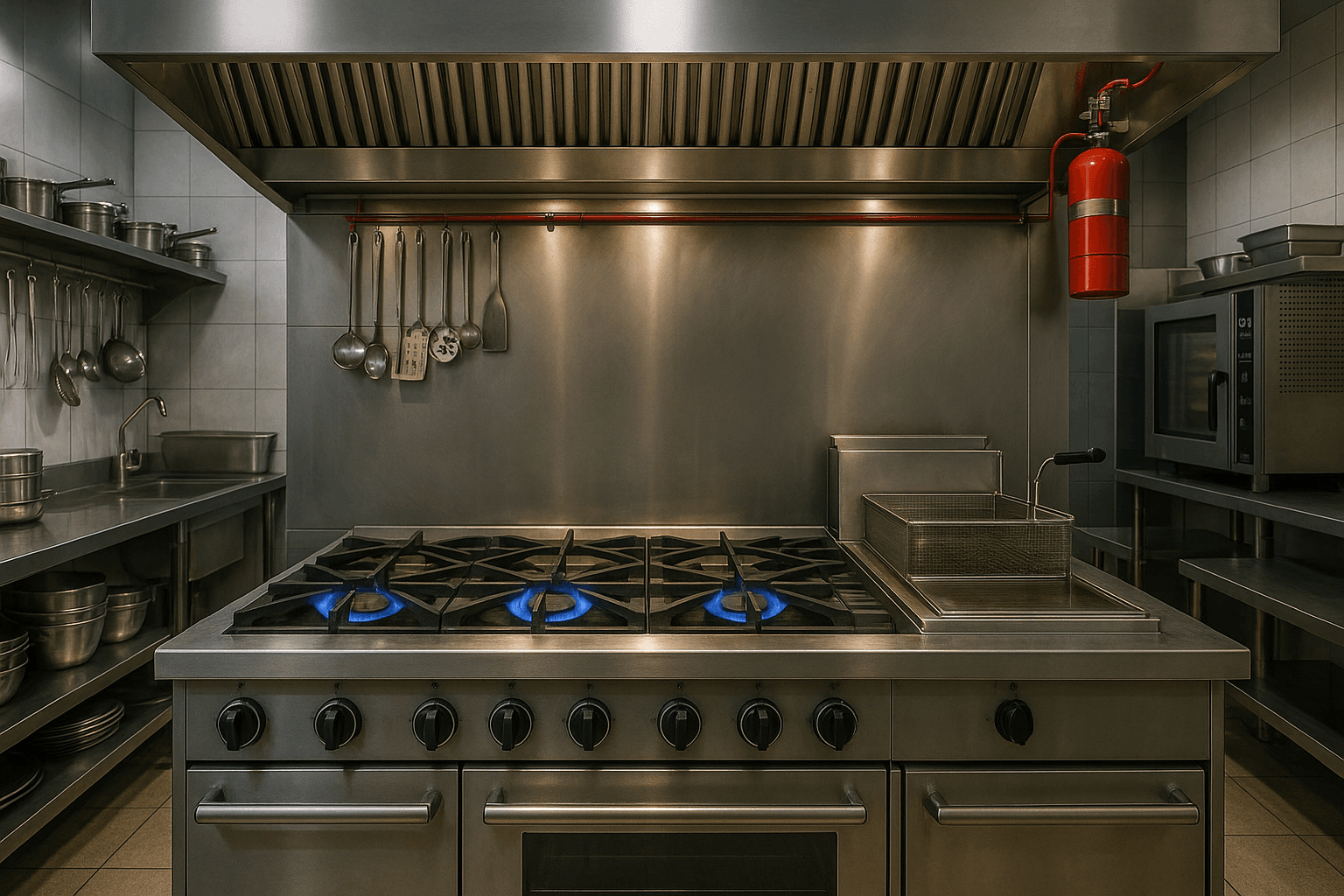

Imagine it’s 7:00 PM on a Friday. The dinner rush is in full swing. The expeller is calling out tickets, the sous chef is searing steaks, and the rhythm of the kitchen is loud, chaotic, and beautiful. It’s a controlled explosion of energy. But there’s another kind of explosion that no one wants to think about, yet it lurks right above your head. Literally.

I’m talking about the Exhaust hood.

You know, that massive stainless steel beast that hums along in the background, sucking up smoke, heat, and—most importantly—Grease. It’s easy to ignore it. As long as the smoke goes up and the air stays relatively clear, most of us assume it’s doing its job. But honestly? That assumption is exactly what leads to trouble. And by trouble, I don’t just mean a failed health inspection; I mean fire. The kind that shuts doors permanently.

Here in Salt Lake City, where the restaurant scene is booming and the air is dry enough to crack your lips, fire safety isn’t something to put on the back burner. It’s the main course. If you run a Commercial kitchen, you already know the stakes. But knowing isn’t the same as doing. Let’s take a walk through the reality of hood safety, strip away the boring technical manual jargon, and look at what actually keeps your kitchen standing.

Wait, How Does Grease Actually Catch Fire?

It seems like a silly question, right? Grease is flammable. We know this. But there is a specific mechanics to it that is worth understanding because it changes how you look at your cleaning schedule. When you are cooking, especially with heavy oils or animal fats, you aren’t just creating smoke; you are vaporizing grease.

Those vapors travel up. They cool down as they move away from the cooktop, and when they hit the cooler metal of the filters, the ductwork, and the Exhaust fan up on the roof, they condense back into a liquid or a sticky solid. Over time, layer upon layer of this “fuel” builds up.

Here’s the thing: You don’t need a direct flame to touch the grease in the ductwork to start a fire. You just need heat. Intense heat. If a flare-up happens on the grill—maybe a burger flamed up a bit too high—that flame can ignite the grease on the filters. If the fans are pulling hard, that fire gets sucked right up into the ductwork like a chimney. It’s a literal wind tunnel feeding a fire with oxygen and fuel.

It happens fast. Faster than you can grab a K-Class extinguisher.

This is why NFPA 96 standards exist. That’s just a fancy way of saying “the rules the fire marshal beats you over the head with.” But they aren’t just red tape; they are written in ash. They exist because too many kitchens have burned down from neglecting the stuff they couldn’t see.

The “Out of Sight” Trap

We are all guilty of it. If it looks clean, it is clean, right? Well, not exactly. Your kitchen staff might do an incredible job scrubbing the backsplash and running the baffle filters through the dishwasher every night. From the floor looking up, that hood looks shiny. It reflects the lights. It looks professional.

But what about the plenum? That’s the area right behind the filters. What about the vertical duct running up three stories? What about the fan blades spinning on the roof?

You can’t see those from the line. And because you can’t see them, it is easy to forget they are slowly getting coated in sludge. I’ve been on roofs in downtown SLC where the grease was so thick around the fan it looked like tar. That isn’t just a fire hazard; it destroys your equipment. An unbalanced fan blade coated in heavy grease wobbles, shakes the motor, and eventually burns it out. Now you aren’t just looking at a cleaning bill; you’re looking at replacing an expensive fan motor and shutting down for a day or two while it gets fixed.

It’s a domino effect. A dirty hood leads to a strained fan, which leads to poor airflow. Poor airflow means smoke stays in the kitchen, making the staff miserable and potentially setting off smoke alarms. And eventually? Fire.

Daily Defense: What Your Staff Can (And Should) Do

Okay, so I’m painting a pretty grim picture here. But it’s not all doom and gloom. There is a lot you can do between professional cleanings to keep things safe. Think of this like brushing your teeth between dentist visits. You still need the dentist, but you don’t want to show up with moss growing on your molars.

First off, clean the filters daily. If you aren’t doing this, start. Tonight. Baffle filters are designed to catch about 70-80% of the grease before it enters the duct. If they are clogged, the air can’t move, and the grease just drips back down onto the grill (which is gross and dangerous).

Here is a quick checklist for your closing crew:

The Daily Grind:

- Pull the filters: Don’t just wipe the front. Take them down.

- Run them through the dish machine: Or soak them in a degreaser solution if you don’t have a high-temp washer.

- Empty the grease cups: You know those little trays under the filters? They overflow fast. Empty and clean them.

- Wipe the hood interior: Just the reachable parts. Get the day’s splatter off before it bakes on.

It sounds simple, but you would be amazed how many kitchens skip this when the rush is over and everyone just wants to go home. I get it. It’s been a long shift. But making this non-negotiable is the first step in commercial kitchen fire safety.

The Pro Clean: Why You Can’t DIY the Ducts

So, if your staff is cleaning the filters, why do you need guys like us? Can’t you just send someone up a ladder with a spray bottle?

Please don’t do that.

Professional hood cleaning isn’t just “cleaning.” It is industrial remediation. We use high-pressure, hot water systems (often treating the water to cut grease instantly) and aggressive, food-safe chemicals that dissolve that polymerized, sticky glue that grease turns into. Plus, we have the tools to reach the entire system. We scrape, we scour, and we polish the stainless steel until it shines.

More importantly, we prevent the mess from destroying your kitchen. A proper hood cleaning involves wrapping the equipment below in plastic, funneling the runoff (which is black, nasty sludge) into containers, and ensuring nothing goes down the drains to clog your grease trap. It is a messy, difficult job that requires specific insurance and certifications.

Also, let’s talk about liability. When the fire inspector comes knocking—or worse, the insurance adjuster after an incident—they want to see a sticker on that hood. They want proof that a certified company cleaned the system according to code. If you cleaned it yourself? Good luck proving it was done right.

Frequency Matters: How Often Should You Call?

This is the most common question I get. “Do I really need you guys here every three months?”

The answer is: It depends on what you are cooking. A vegan raw-food bistro and a 24-hour steakhouse have very different needs. The National Fire Protection Association (NFPA) actually has a breakdown for this. It isn’t random; it is based on fuel load.

If you are charbroiling burgers over an open flame for 12 hours a day, you are generating a massive amount of grease particulate. If you are mostly boiling pasta or steaming veggies, not so much.

Here is a rough breakdown to help you figure out where you fit:

| Type of Cooking Operation | Recommended Cleaning Frequency |

|---|---|

| Solid fuel cooking (Wood-burning ovens, charcoal grills) | Monthly |

| High-volume fast food / 24-hour operations (Burgers, fryers, woks) | Quarterly (Every 3 Months) |

| Standard sit-down restaurant (Moderate volume) | Semi-Annually (Every 6 Months) |

| Low-volume cooking (Churches, day camps, seasonal businesses) | Annually |

Most standard restaurants in Salt Lake City fall into that Quarterly or Semi-Annual bucket. But don’t guess. Ask a professional to inspect the buildup after a month or two. We can tell you exactly how fast you are accumulating grease.

The Roof: Where the Real Mess Lives

I mentioned this earlier, but I want to circle back to it because it is that important. The roof is usually a disaster zone for restaurants that don’t keep up with maintenance. When the grease fan spins, it flings grease out. If you don’t have a proper Containment system—like a grease box with a pillowy Filter inside—that grease runs right onto your roof membrane.

Here is why that sucks:

- Roof Damage: Grease is acidic. It eats through rubber roof membranes. Eventually, you will have a leak. And fixing a commercial roof isn’t cheap.

- Fire Risk: If a fire travels up the duct, and there is a pool of grease on the roof, the fire spreads to the structure of the building instantly.

- Environmental Issues: When it rains (and yes, it does rain in Utah occasionally), that grease washes down the storm drains. The city hates that. You can get fined heavily for contaminating stormwater runoff.

A good hood cleaning service checks the roof every time. We change the grease pillows, clean the fan blades, and make sure the roof around the fan is clean. It’s part of the package.

Living and working in Utah brings its own set of quirks. We have distinct seasons. In the summer, those rooftop fans are baking in 100-degree heat. That heat makes the grease runnier, making it seep into cracks and crevices you didn’t know existed. In the winter, the cold can make grease harden faster, creating thick blockages that reduce airflow efficiency.

Plus, we have a very diligent Fire Marshal presence in Salt Lake City and the surrounding valleys. They are sharp. They know what to look for. They aren’t just checking to see if you have a fire extinguisher; they are looking for clean access panels on your ducts. They are looking for the date on your hood sticker.

There is a certain peace of mind that comes with knowing you are compliant. It lets you focus on the food. You shouldn’t be worrying about duct fires while you’re trying to perfect a new mole sauce or manage the Saturday night waitlist.

Signs Your Hood Needs Attention NOW

You don’t always have to wait for the scheduled date. Sometimes, the system screams for help. You just have to listen. Or smell.

If you walk into your kitchen and it smells like… well, like yesterday’s food, that’s a bad sign. It means the exhaust isn’t pulling the air out. If you see smoke lingering in the dining room, that’s an emergency. Customers hate it, and it means your capture rate is failing.

Another subtle sign? Noises. If that fan starts rattling or making a grinding sound, the bearings might be shot or the blades might be off-balance from grease weight. Don’t ignore the rattle. The rattle is expensive if left alone.

And obviously, if you see grease dripping from the hood seams. That isn’t just a “wipe it up” moment; that means the reservoir inside the duct is full and leaking. That is a critical failure of the cleaning cycle.

The Relationship with Your Cleaner

You know what? Finding a vendor you trust is hard. Whether it’s your food supplier, your linen service, or your hood cleaner. You want someone who shows up when they say they will. You want someone who doesn’t leave your kitchen floor looking like a swamp.

A good Hood Cleaning Company is a partner in your business. We act as a second set of eyes. We might spot a frayed wire on the fan motor or a broken hinge on the access panel. We let you know before it becomes a crisis. We take photos of the “before and after” so you can verify the work was done—because, again, you aren’t crawling into the ductwork to check.

Transparency is key. If a cleaner comes in, spends 45 minutes, and leaves? They didn’t clean it. They polished the hood and left. A real cleaning takes time, effort, and sweat. It’s dirty work, but we love it because we know we are keeping your doors open.

Wrapping It Up: It’s About Longevity

At the end of the shift, you want your restaurant to be around for a long time. You want to build a legacy in this city. A kitchen fire is the fastest way to end that dream. But it is also the most preventable.

By combining daily diligence from your staff with a robust, professional cleaning schedule, you turn a major risk into a manageable maintenance task. You protect your building, your employees, and your customers. Plus, the food just tastes better when it isn’t being cooked in a smoke-filled room.

So, take a look up the next time you step on the line. Is that hood shining? Is the airflow strong? If you aren’t sure, it might be time to ask for a professional opinion. Don’t wait for the rattle or the smell. Stay ahead of it.

Ensuring your kitchen is safe and compliant shouldn’t be a headache. If you’re in Salt Lake City and want a no-nonsense assessment of your hood system, or if you just need a cleaning crew that actually cleans, reach out to us. We’d love to help keep your kitchen running smooth and safe. Give us a call at 801-853-8155 or simply Request a Free Quote today.